Universal models for rotational molding equipment.

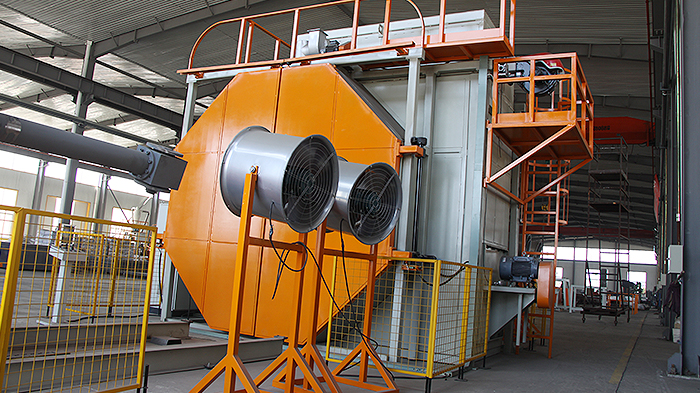

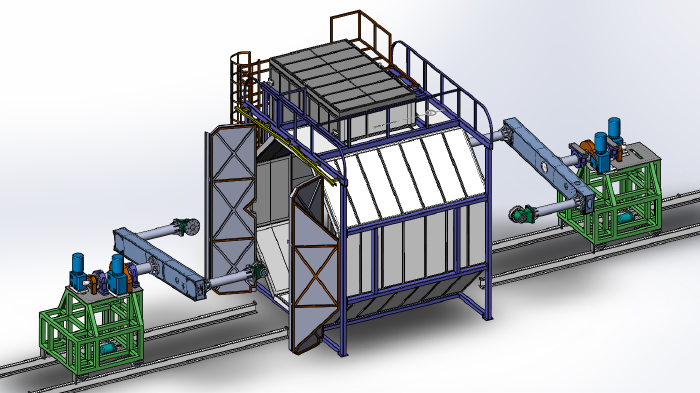

Fangda shuttle type series rotary molding machines are specially designed and manufactured to solve the problem of stable and efficient production for customers.

The same equipment produces products with different process parameters online (with significant differences in product thickness, shape, or molding time) without affecting each other;this kind of rotomolding device has the characteristics of good stability, strong functionality, and wide applicability.

Fangda shuttle type rotational molding equipment is very suitable for

customers who have just entered the rotational molding market. Two working arms

share a heating chamber and shuttle back and forth to heat and cool/disassemble

the mold. Each working arm controls the process separately, making it very

suitable for two working arms to produce rotational molded products with

different process parameters.

● Available heating sources: natural gas, liquefied gas, or diesel;

● Efficient insulation heating room with lower energy consumption;

● Each arm operates independently and does not interfere with each

other;

● Interlock function to ensure safe and stable operation of

equipment;

● Real time monitoring of heating chamber temperature to ensure product

quality;

● Process formula storage function, convenient for production

management;

● The touch interface has complete and reasonable functions, making it

easy to operate;

● Fault self check function, convenient for maintenance;

● Can achieve remote fault diagnosis;

● Fully automatic control system, easy to operate and time-saving, with

high production efficiency.

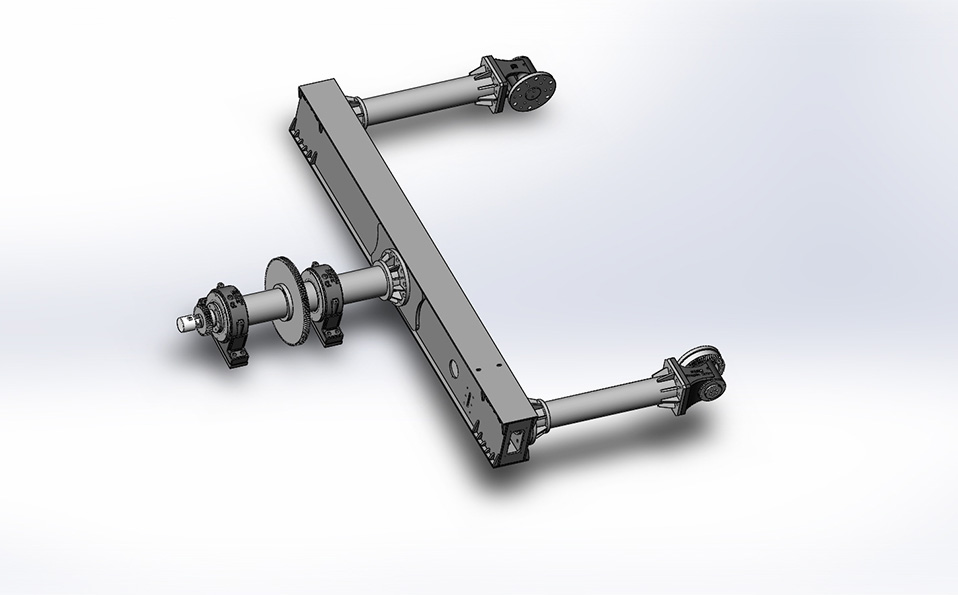

● Equipped with arm type: straight arm, L-arm, C-arm,and U-arm,can be

freely selected;

● Optional temperature measurement system inner the mold;

● Optional semi-automatic weighing and feeding system;

Model | Equipment footprint size | Internal dimensions of heating chamber (m) | |||

L(m) | W(m) | W1 | H(m) | ||

FD2-1600 | 8.5 | / | 3.9 | 2.8 | φ1.6x1.6 |

FD2-2100 | 11.0 | / | 4.9 | 3.5 | φ2.1x2.1 |

FD2-2600 | 13.0 | 8.1 | 5.6 | 4.0 | φ2.6x2.6 |

FD2-3100 | 14.7 | 9.3 | 6.1 | 4.5 | φ3.1x3.1 |

FD2-3600 | 16.3 | 10.0 | 6.8 | 5.0 | φ3.6x3.6 |

FD2-4100 | 18.0 | 11.0 | 7.5 | 5.5 | φ4.1x4.1 |

FD2-4600 | 20.0 | 11.5 | 8.0 | 6.0 | φ4.6x4.6 |

FD2-5100 | 22.0 | 12.0 | 8.7 | 6.5 | φ5.1x5.1 |

FD2-5600 | 24.0 | 12.5 | 9.2 | 7.0 | φ5.6x5.6 |

FD2-6100 | 26.0 | 13.0 | 10.0 | 7.5 | φ6.1x6.1 |

FD2-6500 | 28.0 | 14.0 | 11.0 | 8.0 | φ6.5x6.5 |

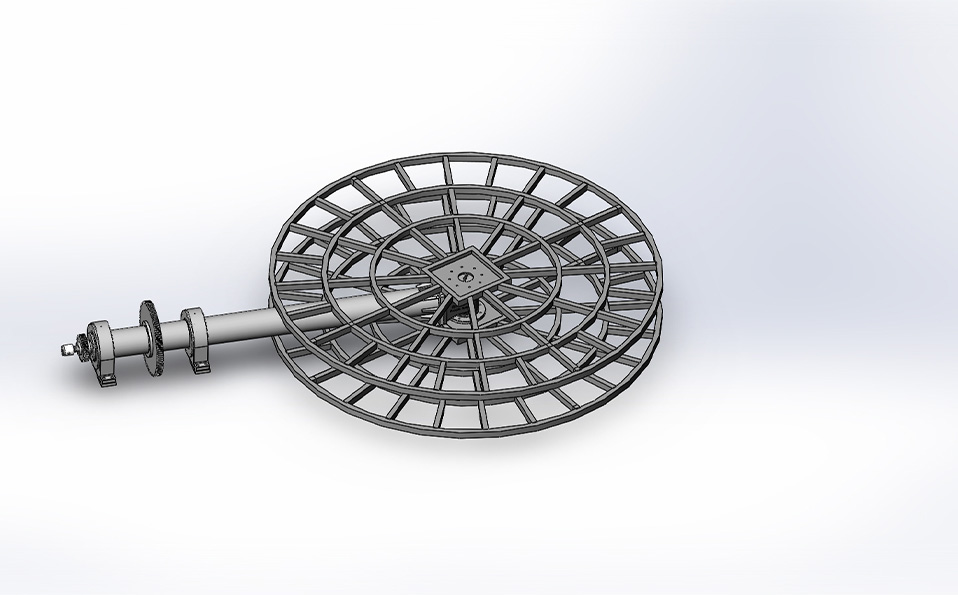

Straight arm

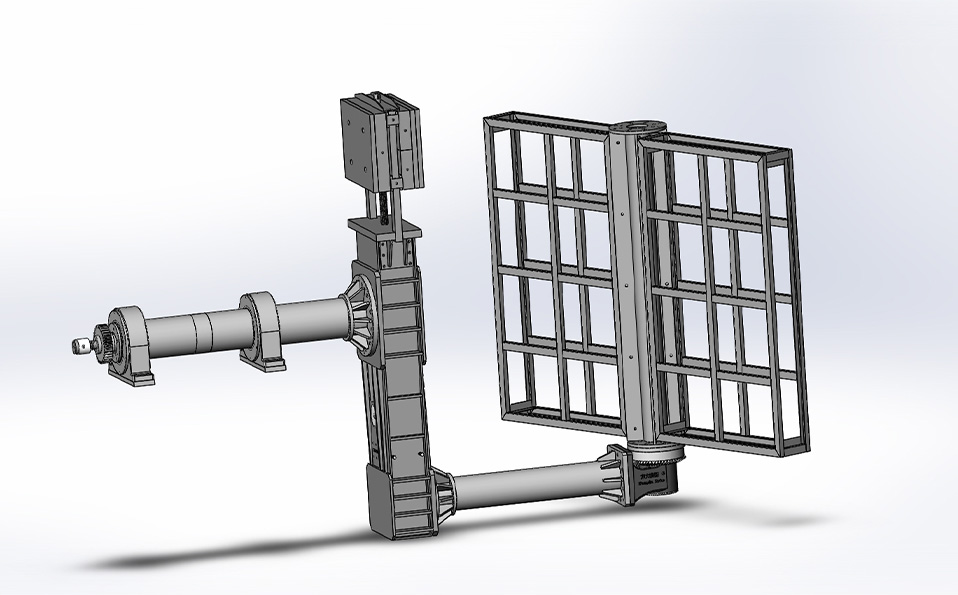

L-arm

C-arm